Advanced Automatic Spray Gun Technology for Industrial Coatings #

Ranox is recognized for its expertise in manufacturing OEM/ODM automatic paint spray guns, offering a comprehensive selection tailored to diverse industrial requirements. Our solutions address the needs of the industrial coating market, providing options for both liquid and powder coatings, with or without electrostatic effects. Each spray gun is engineered for high performance, fine atomization, and superior surface quality, helping businesses reduce maintenance, minimize cleaning, increase productivity, and save on paint usage.

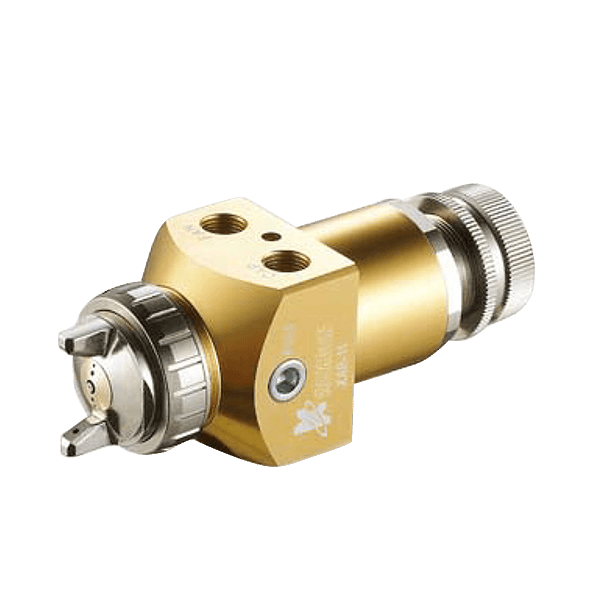

Medium Pressure Automatic Paint Spray Gun

Medium Pressure Automatic Paint Spray Gun

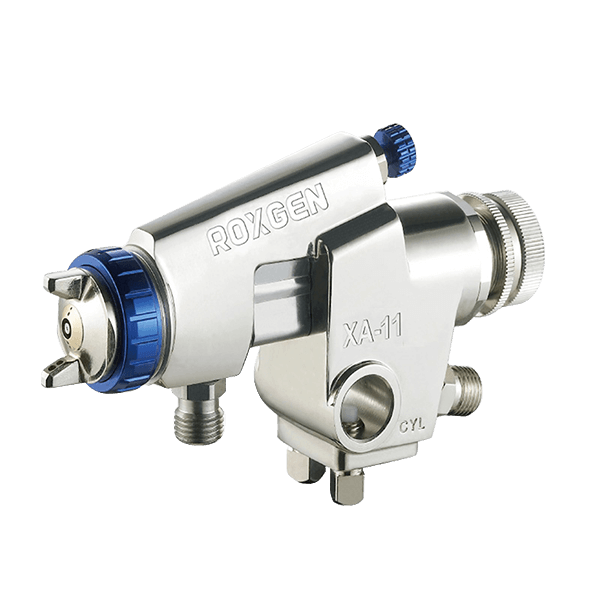

(LVLP) Low Pressure Automatic Spray Paint Gun

(LVLP) Low Pressure Automatic Spray Paint Gun

Round Pattern Automatic Spray Paint Gun

Round Pattern Automatic Spray Paint Gun

Product Range #

- Medium Pressure Automatic Spray Gun: Designed for stable coating quality, these guns atomize and distribute fluids with a high adhesion rate. Ideal for integration with automatic spraying equipment.

- Low Pressure (LVLP) Automatic Spray Paint Gun: Suitable for large area finishes, these guns allow external control of atomizing and spray air, making them compatible with robotic systems.

- Round Pattern Automatic Spray Gun: Engineered for mounting on robotic arms or automatic painting machines, these guns are versatile for applications such as adhesive glue, spot marking, lubricating oil, and release agents.

Why Choose Ranox Automatic Spray Guns? #

- Precision and Efficiency: Our automatic painting guns are built for optimal performance, ensuring consistent spray quality and efficient material transfer, which leads to minimal wastage and high productivity.

- Ergonomic Design: With a focus on user comfort, our spray guns feature ergonomic designs that reduce operator fatigue. Their compact and lightweight construction enhances maneuverability and efficiency.

- Homogeneous Spraying: Ranox equipment is engineered to deliver uniform coatings, minimizing overspray and creating a cleaner work environment. This results in impeccable finishes and reduced material consumption.

- Versatility: Our automatic spray guns are suitable for a wide range of applications, delivering reliable results across various industries.

Commitment to Innovation #

Ranox continues to lead in automatic spray gun technology, offering advanced atomization, precise control systems, and ergonomic designs. All components, including the body, head (air cap), and nozzle, are manufactured in-house using high-quality materials. This commitment to quality and innovation ensures our products meet the evolving demands of industrial coatings and finishes.

For businesses seeking tailored solutions, Ranox provides OEM services to address unique industrial requirements. Explore our OEM Services or Request a Quote to discover how we can support your coating processes.

Frequently Asked Questions About Automatic Paint Spray Guns #

What is an automatic paint spray gun? #

An automatic paint spray gun is a precision tool used in industrial and commercial settings to apply coatings such as paint, varnish, or other finishing materials. Unlike manual spray guns, automatic models are typically mounted on machinery, robots, or fixed fixtures and are controlled electronically or pneumatically. They feature mechanisms for controlling spray patterns, fluid flow rates, and atomization, ensuring precise and repeatable results.

Key Features:

- Automation for consistent and efficient operation

- Regulated spraying via external controls (timing, pressure, material flow)

- Even application with minimal waste

- Durable construction for high-volume, repetitive tasks

Main Components:

- Nozzle (defines spray pattern)

- Needle (controls paint flow)

- Air Cap (combines air and paint for atomization)

- Control Valves (regulate air and material flow)

- Mounting Brackets (for integration with automated systems)

Automatic spray guns can be seamlessly integrated into production lines for streamlined workflows.

How do automatic paint spray guns differ from manual air spray guns? #

| Feature | Manual Air Spray Guns | Automatic Paint Spray Guns |

|---|---|---|

| Operation Mechanism | Manual trigger control | Automated paint feed, no trigger pulling |

| Ideal For | Detailed work, small projects | Large areas, high-production environments |

| Control | High degree of control | Prioritizes speed and efficiency |

| Efficiency | Slower for large areas | Faster, suitable for extensive projects |

| Fatigue | Can cause arm fatigue | Less physical strain due to automation |

| Price | Generally more affordable | Higher initial cost, long-term savings |

| Portability | Lightweight, easy to maneuver | May be heavier and bulkier |

| Versatility | Various finishes with different spray tips | Designed for consistency |

| Maintenance | Simpler to clean and maintain | More complex cleaning requirements |

Which industries benefit most from automatic paint spray guns? #

Automatic paint spray guns are widely used in:

- Automotive Industry: For painting vehicle bodies and components, ensuring consistent, high-quality finishes in production lines.

- Manufacturing: For coating consumer goods and industrial equipment, streamlining processes and reducing labor costs.

- Consumer Goods: For finishing products like furniture and appliances, enhancing appearance and maintaining quality.

- Electronics: For coating circuit boards and components with protective finishes, requiring high precision.

- Woodworking: For applying stains, paints, and finishes to furniture and cabinetry, ensuring smooth, even coats.

- Textile and Leather: For spraying dyes, protective finishes, or waterproofing agents on fabrics and leather goods.

What is the purpose of using an automatic spray gun? #

The main objectives of using an automatic paint sprayer include:

- Improved Efficiency: Automates the coating process, reducing time and labor for large-scale or repetitive tasks.

- Consistency in Application: Delivers uniform coating thickness, minimizing defects like streaks or drips.

- Material Savings: Optimizes coating material usage, reducing waste and ensuring better coverage.

- Enhanced Productivity: Supports continuous operation in automated lines, increasing throughput.

- Versatility: Handles a wide range of coatings and surfaces, from metals to plastics and ceramics.

- Cost-Effectiveness: Lowers manual labor costs and reduces rework due to inconsistencies.

- Health and Safety: Minimizes worker exposure to fumes and chemicals, and can be operated remotely for a safer environment.