The Role of Paint and Air Hoses in Spraying Systems #

Paint hoses and air hoses are essential components in any professional spraying setup, each serving a distinct purpose to ensure optimal performance and finish quality.

Paint Hoses: Ensuring Consistent Coating Delivery #

The primary function of a paint hose is to transport coatings or paint from the source to the spray gun. Due to the chemical properties of paint, the interior of these hoses is specially treated to prevent sediment buildup and corrosion. This treatment helps maintain the purity and steady flow of the paint, which is crucial for achieving a uniform spray pattern. Whether used in low or high-pressure systems, a quality paint hose ensures reliable and consistent paint delivery, supporting superior spray results.

Air Hoses: Delivering Stable Air Pressure #

Air hoses are designed to supply compressed air to the spray gun, providing the necessary pressure for atomization. Constructed from lightweight yet durable materials, these hoses are engineered to withstand high pressures while maintaining flexibility. Their design ensures a stable and continuous airflow from the compressor or air supply source, which is vital for consistent atomization and overall spray quality throughout the painting process.

Product Range #

Ranox offers a comprehensive selection of hoses tailored for various spraying applications:

- Paint hoses

- Air hoses

- Antistatic paint hoses

- Antistatic air hoses

- Air braided hoses

- Paint braided hoses

- High pressure hoses

Below are some of the featured products in this category:

Each product is designed to meet specific requirements, whether for standard, antistatic, or high-pressure applications. For more details on each hose type, visit the respective product pages.

For inquiries or further information, please refer to the Contact page.

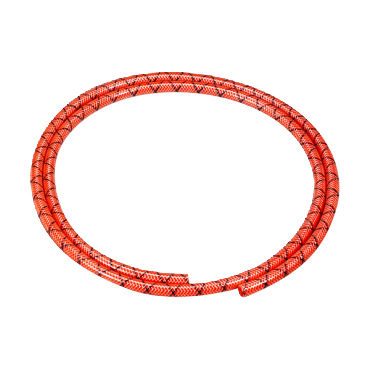

Braid Paint Hose for Sprayers

Braid Paint Hose for Sprayers TWIN HOSE

TWIN HOSE Antistatic-air-hose (Paint-Hose)

Antistatic-air-hose (Paint-Hose) PU Paint Hose

PU Paint Hose